Life safety ropes are important in rescue work, firefighting, climbing, and other extreme challenges that are made or affected by human life, which is in need of support in terms of its safety and reliability. These ropes have been developed to withstand heavy loads, tension, and a tough environment to break. The construction method depends on the performance of the rope when stressed and also the safety of the user.

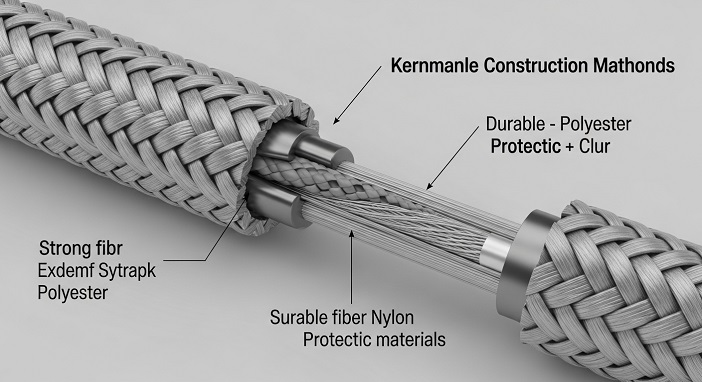

The kernmantle method is one of the diverse methods of rope constructions, a method that is required and accepted to be used in life safety applications. It is made with a powerful inner core (kern) giving the majority of the rope strength, and an outer sheath (mantle) that is abrasion-resistant and damage-resistant. The kernmantle design is of a high level of safety according to the international standards, and it is adopted due to its high level of strength, quality, flexibility, and reliability in emergency cases where safety is not compromised in any way.

Life Safety Ropes

Life safety ropes are designed with special consideration that they will have human loads in the event of rescue, downward, or fall prevention. They are contrasted with utility ropes, which are exclusively used on equipment or on light-duty. Since the safety of a person is conditional upon him, life safety ropes should adhere to the safety standards established by such organizations as NFPA (National Fire Protection Association), OSHA (Occupational Safety and Health Administration), and UIAA (International Climbing and Mountaineering Federation).

The construction type defines how the rope carries load, stretches under stress, and resists wear. Engineers and construction estimating consultants working in safety-critical sectors often assess the rope’s strength, material composition, and manufacturing quality to ensure compliance with safety regulations and project requirements. Proper rope construction is essential for maintaining stability and protecting users in life-threatening situations.

The Kernmantle Process Of Construction

The most common method of construction used universally to construct the life safety rope is the kernmantle technique. The name is based on two German words:

- Kern, meaning “core”

- Mantle meaning “sheath”

This design will have two major components:

- The Kern (Core): Core constitutes approximately 702/3rd of the strength of the rope. It consists of parallel or twisted strands of synthetic fibres like nylon or polyester, to take the majority of the tensile load.

- The Mantle (Sheath): The outer sheath provides defense against abrasion, UV light, dirt, and mechanical damage to the core. It also provides the rope structure, flexibility, and grip.

These layers are combined to form a rope that is durable and strong and has a manageable weight, and good handling characteristics.

Types of Kernmantle Ropes

Kernmantle ropes are available in two major types, each used in a different life safety application:

Kernmantle Rope, Low-Stretch (static): This is a type possessing a low degree of stretch, typically less than 2% in typical loads. It is employed in rescue work, rappelling, and rope access work in which controlled movement and stability are vital.

High-Stretch Kernmantle Rope: The stretch of this type is up to 30% when loaded. It is made to climb or in any case where falling may occur, since the rope is not very rigid, and thus during falls, the rope can absorb the shock, and the impact may not affect the user.

Both the static and dynamic kernmantle ropes are thoroughly tested to the life safety standards, and only after that, they are approved to be used.

Why The Kernmantle Method Is Preferred

Kernmantle construction is the best to use in life safety ropes due to the existence of strength, protection, and performance. Here’s why:

Superior Strength:

Most of the load is supported by the core fibers, and this gives high tensile strength. This enables the rope to sustain heavy weights of human beings without breaking.

Abrasion Resistance:

The outer sheath helps protect the inner core against friction, dirt, or sharp edges that can damage the rope, extending the service life.

Controlled Elongation:

The kernmantle rope can be designed to give the exact amount of stretch needed by the circumstances, either by limiting motion or absorbing impact, depending on whether it is dynamic or static.

Smooth Handling:

This is because the sheath makes the rope easy to handle, knot, and coil, but without being too stiff.

Inspection And Maintenance:

The sheath can easily be spotted in case of any damage, and rescuers can determine the condition of their ropes only to replace them when needed.

Types Of Life Safety Rope Materials

Materials are also significant in safety. Most life-saving ropes consist of synthetic fibers, e.g:

- Nylon: It is resistant to shock loads, elastic, and strong. Ideal for dynamic ropes.

- Polyester: It is less stretchable and more resistant to chemicals and UV rays. Common in static ropes.

- Aramid fibers (e.g., Kevlar, Technora): These are used in high-heat and abrasion-resistant applications in specialized rescue.

Every material is chosen depending on the purpose (use of the ropes), climate, and safety.

Life Safety Rope Standards And Testing

Testing of life safety ropes is done to stringent international standards. The most common include:

- NFPA 1983: Standard of Life Safety Rope and Equipment Emergency Services.

- UIAA 101: Standard of safety of climbing ropes.

- EN 1891: European standard of static ropes.

These criteria assess the breaking strength, elongation, abrasion resistance, knotability, and chemical longevity. The only ropes that pass these tests and therefore are deemed to be suitable to be used in life safety.

Maintenance And Inspection Of Life Safety Ropes

A powerful rope may not be safe as long as it is not well cared for. It should be inspected regularly to detect signs of wear, cuts, contamination, or chemical exposure.

The major maintenance measures are:

- Washing ropes with tame soap and water.

- Exposure to oils, acids, and high temperatures should be avoided.

- Rope storage in a cool and dry place and out of direct sunlight.

- Do not retire until the sheath is damaged or the core is found to be uneven.

The recommended service life of most life safety ropes is 5 to 10 years, based on use and condition.

Other Rope Construction Methods (And Why They’re Not Used For Life Safety)

Rope constructions such as laid (twisted) rope and braided rope are generally used for general purposes; however, they do not possess the safety properties needed to be used in life safety applications.

- Laid Ropes: Fibers that are twisted are also likely to unravel and are weak in abrasion, as well as spin during loading.

- Braided Ropes: Although malleable, they frequently do not match the structural balance and core strength of kernmantle ropes.

Thus, kernmantle construction is a standard and safe solution to all professional rescue and safety operations.

Conclusion

The kernmantle method of construction is the required and recognized standard for life safety ropes. Its dual-layer design, the strong inner core, and a protective outer sheath offer unmatched strength, durability, and flexibility. Whether in firefighting, mountain rescue, or industrial safety operations, kernmantle ropes ensure reliability when lives depend on them. Regular inspection, maintenance, and adherence to safety standards further guarantee their effectiveness in critical situations. In short, when it comes to life safety, the kernmantle rope construction is not just a choice, it’s a necessity.

FAQs

What Is The Required Method Of Construction For Life Safety Rope?

The kernmantle method of construction is required, featuring a strong inner core (kern) and a protective outer sheath (mantle) for maximum strength and safety.

What Materials Are Used In Life Safety Ropes?

Most life safety ropes are made of synthetic fibers such as nylon, polyester, or aramid fibers like Kevlar for superior strength and resistance.

How Often Should Life Safety Ropes Be Replaced?

Life safety ropes should generally be replaced every 5 to 10 years, or immediately if there are signs of wear, damage, or chemical exposure.